Accurate knowledge of COGM helps in setting competitive prices for your products while ensuring profitability. This understanding is essential for financial modeling and planning, as precise COGM data is vital for creating accurate forecasts and budgets. Direct material costs include the expenses for raw materials used directly in manufacturing products. To find this, add the beginning inventory of raw materials to the purchases made during the period, then subtract the ending inventory of raw materials.

Formula to Calculate Cost of Goods Manufactured

It breaks down all your expenses — materials, labor, and other production costs — so you know where your money is going. The COGM schedule gives a structured summary of everything tied together — total manufacturing costs with inventory change to arrive at the final price of goods completed. Manufacturing overhead is a part of the COGM formula; more specifically one of the components in the total manufacturing cost part. However, what should we include into manufacturing overhead is a complicated matter and doesn’t have a certain answer. Next, input the total wages or salaries paid to workers directly involved in the manufacturing process. This includes the labor costs for employees who work on the assembly line, machinery, or any other tasks directly related to production.

Formula to Calculate Cost of Goods Manufactured

- How to track and manage your raw material inventory to increase profits, become more organized and grow your business.

- At the same time, calculating the CGOM requires you to already have a ton of information on hand.

- Because the closing carrying balance is used as the starting balance for the following period, it belongs to the previous accounting period.

- They’ll be able to adapt quickly to changes in the market and stay ahead of the competition.

But sales revenue only tells part of the story; you also have how to calculate cogm to factor in the costs of generating your inventory in the first place. For this, businesses use a metric called the cost of goods manufactured (COGM). After learning the COGM formula, you may now recognize the need for software to enhance the efficiency of your COGM calculations.

Step 6: Apply the COGM Formula

- There was this one company that started using automated machines to do the work of three people.

- Typically, businesses whose principal line of business is manufacturing create a separate schedule to calculate the cost of goods manufactured to determine their cost-effectiveness.

- Total manufacturing cost (TMC), also called total cost of production, is the all-in number for what it takes to make goods during a specific period.

- When a company removes raw materials for manufacturing, it must record those removals on the debit side of the raw materials inventory.

- To illustrate this, let’s consider an example of a fictional manufacturing company, XYZ Inc.

- To calculate COGM, you’ll need to account for the value of WIP inventory at the beginning and end of the production period.

- Cost of goods sold (COGS) is the cost of selling products, in other words the cost of finished inventory ready for sale.

The key is to include all indirect costs that are necessary for production. The COGM journal entry records the costs incurred by a company during the manufacturing process. This entry is crucial for accurately reflecting the manufacturing expenses in the company’s accounting records. The cost of Goods Manufactured (COGM) helps you understand exactly how much Bakery Accounting it costs to make your products.

Everything to Run Your Business

It provides a clear picture of the total production costs and is vital for various financial decisions. Our COGM calculator simplifies the process of determining this critical figure, allowing businesses to make informed financial choices. By diligently tracking these expenses, manufacturers ensure that the direct materials costs contribute accurately to the overall COGM.

- As a maker, one of the first things to realise is that you are not just a retailer of your goods – you are also a manufacturer of them.

- Manufacturing overhead includes all other production costs that are not directly tied to materials or labor.

- Careful adjustment for WIP ensures that you are not overestimating or underestimating your production costs, which can lead to more accurate pricing and profitability assessments.

- It’s important to note that COGS usually excludes indirect (overhead) expenses.

- After the calculation, the COGM value is then transferred to a final inventory account.

How do I easily calculate Cost of Goods Sold (COGS)? A step-by-step guide.

Aligning the calculation period with business needs helps capture relevant cost fluctuations and insights. Here is a step-by-step guide to help companies accurately calculate COGM, empowering them to make well-informed business decisions with confidence. From the bill of materials to the production planning features, the solution helps you stay on top of your game and keep your company’s competitive edge. After calculating its COGM for the year, a business transfers the value to a completed goods inventory account. This final inventory report pertains to services, goods, and products made available to consumers.

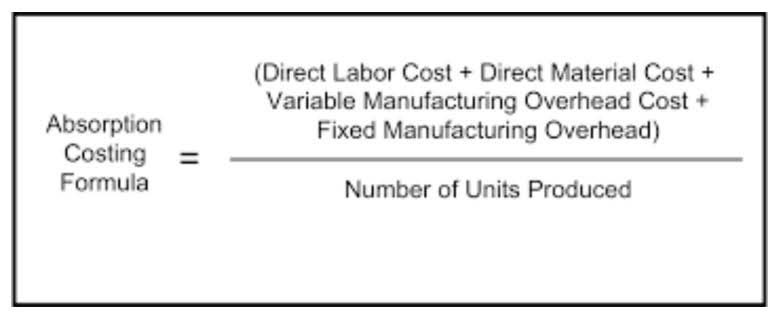

COGM will ultimately influence your pricing strategies and decision-making processes. The Cost of Goods Manufactured (COGM) Calculator is an essential tool for manufacturers looking to track their production costs accurately. By understanding how COGM is calculated and using this tool, businesses can make informed decisions that help control costs, set profitable prices, and optimize production processes. The statement starts with the beginning inventory of work-in-progress, adds the total manufacturing costs, and deducts the ending work-in-progress inventory to arrive at the COGM figure.

- Direct materials cost and direct labor cost were calculated; there is only the manufacturing overhead cost left to reach the total manufacturing cost.

- The amount of COGS includes the cost of materials and labor that were used directly for the production of goods.

- This is the cost of the raw resources the company used to create its goods.

- It is important to take into account both the starting and end balances, much like with raw material and work in process inventories.

- Cost of goods manufactured schedule accurately provides insight into the production costs and helps ensure that financial statements reflect the true cost of goods produced.

It will be feasible to plan for resource usage and volume production over time. Additionally, implementing the necessary changes will boost the business’s net profits. In general, COGM provides the business with critical information about the cost variables. We show you the easy (and surefire way!) to calculate your Cost of Goods Sold (COGS) accurately and fixed assets with a minimum of fuss.